Precision Fermentation®, a leading biochemistry technology solutions provider, and The 5th Ingredient®, a leading brewery operations management software company, announced this week the integration of real-time fermentation data with a brewery operations management system, delivering live fermentation data – dissolved oxygen, pH, gravity, pressure, temperature, and conductivity – directly into The 5th Ingredient’s flagship brewery management software, Beer30TM. The automated fermentation data collection enables brewery staff to save time and effort by dramatically reducing the need for manual fermentation sampling and logging.

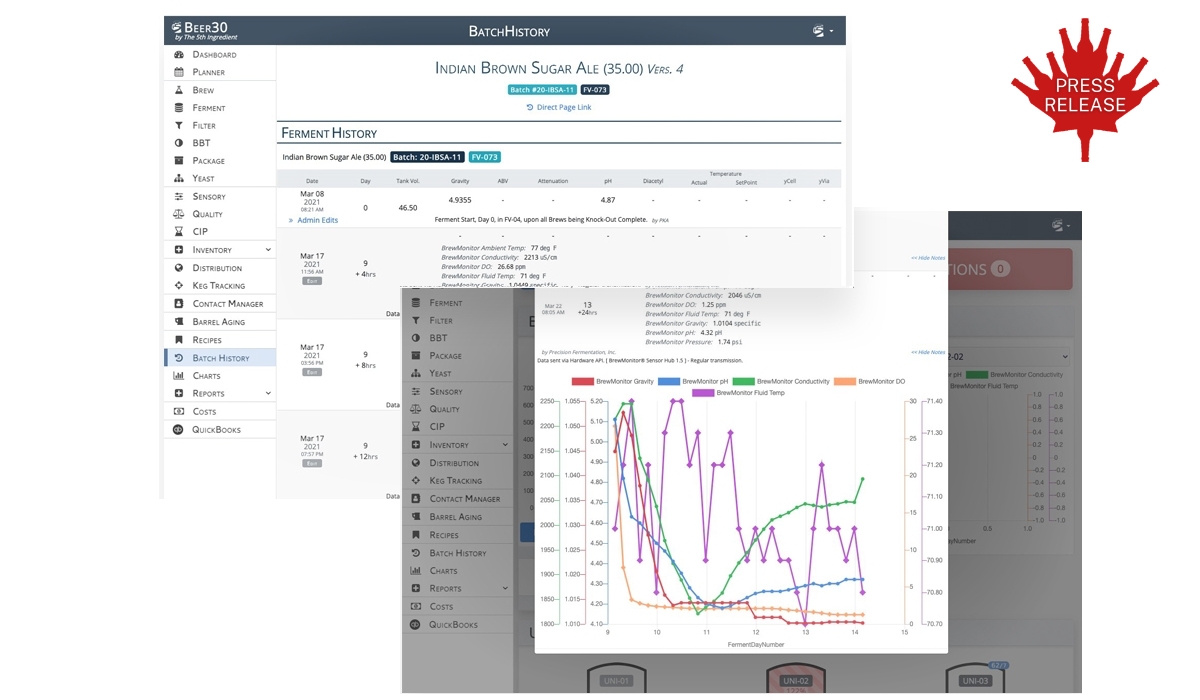

“We are thrilled to be part of another first in our industry,” said Jared Resnick, founder and CEO of Precision Fermentation. “Accessing real-time data from the BrewMonitor Sensor Hub® from Beer30’s software suite allows brewers to track, from a single dashboard, all operational actions and ingredients that produce each batch, side-by-side with precise outcomes of these factors as data is streamed directly from inside the fermentation tank. Beer30 excels in management of all elements that go into each batch, including precise ingredient information, tank management, CIP tracking and so much more. Adding live, high-resolution fermentation data not only greatly reduces the overhead and inconsistency of manual sampling, but it also finally puts in the hands of brewery staff the ability to correlate detailed results from all brewery processes at a single glance and with high accuracy. This integration offers a leap forward in quality assurance that can have a major impact on any brewery’s bottom line.”

“With this new integration, we continue to pioneer and evolve a new wave of brewery data management software,” said Pulkit K. Agrawal, founder and CEO of The 5th Ingredient. “We are committed to helping breweries #BrewBetterBeer and helping brewers take a more confident, proactive approach to their processes, rather than a reactive one. From a quality perspective, the first 3-4 days of fermentation are crucial, and with BrewMonitor fermentation data sent directly to Beer30, breweries have even more flexibility to make better data-driven decisions, powered by smart sensor technology. Beer30’s data visualization tools allow users to graph all data, identify trends and anomalies, and compare a beer brand across multiple batches. By combining BrewMonitor’s real-time data with Beer30’s robust Batch History functionality, breweries can take their grain-to-glass analysis to the next level. Whenever two of the top innovators in an industry come together, the industry wins as a whole.”