Dalum has developed CO2 Recovery Units that promote a circular utilization of a brewery’s own CO2, by recovering the CO2 from the fermentation process. It is collected, cleaned, liquified, stored and is then ready to be used in all steps of future beer production, “It’s just like printing money,” jokes Mike Murphy of Lervig Brewery. Dalum estimates that a 20,000 barrel brewery could recapture 50 tons of CO2 emissions and save 100 tons of emission by not purchasing CO2 from gas suppliers. This is equivalent to taking more than 32 cars off the road*. Svaneke Brewery, in Denmark, was able to achieve verified carbon neutrality through their sustainability efforts, including the installation of a Dalum CO2 recapture unit in 2021 (featured in Scandinavian Brewers’ Review March, 2023 Issue).

Two newest DALUM CO2 Recovery Units installed at Lervig Brewery in Norway

Dalum, which installed their first CO2 Recovery Plant in 2020 at Danish brewery Ørbæk Bryggeri is having great success with the unit. “It has been a joy working with Dalum…it has been a great addition to our brewery,” said Andrea Falkenberg of Ørbæk. Positive feedback from additional units installed in Europe has led Dalum to launch in the US, where increasingly, craft breweries focus on preparing for a greener future and CO2 supply sourcing. The US office is based in Algoma, WI led by John Kiedrowski, formerly of Miller Brewing Co.

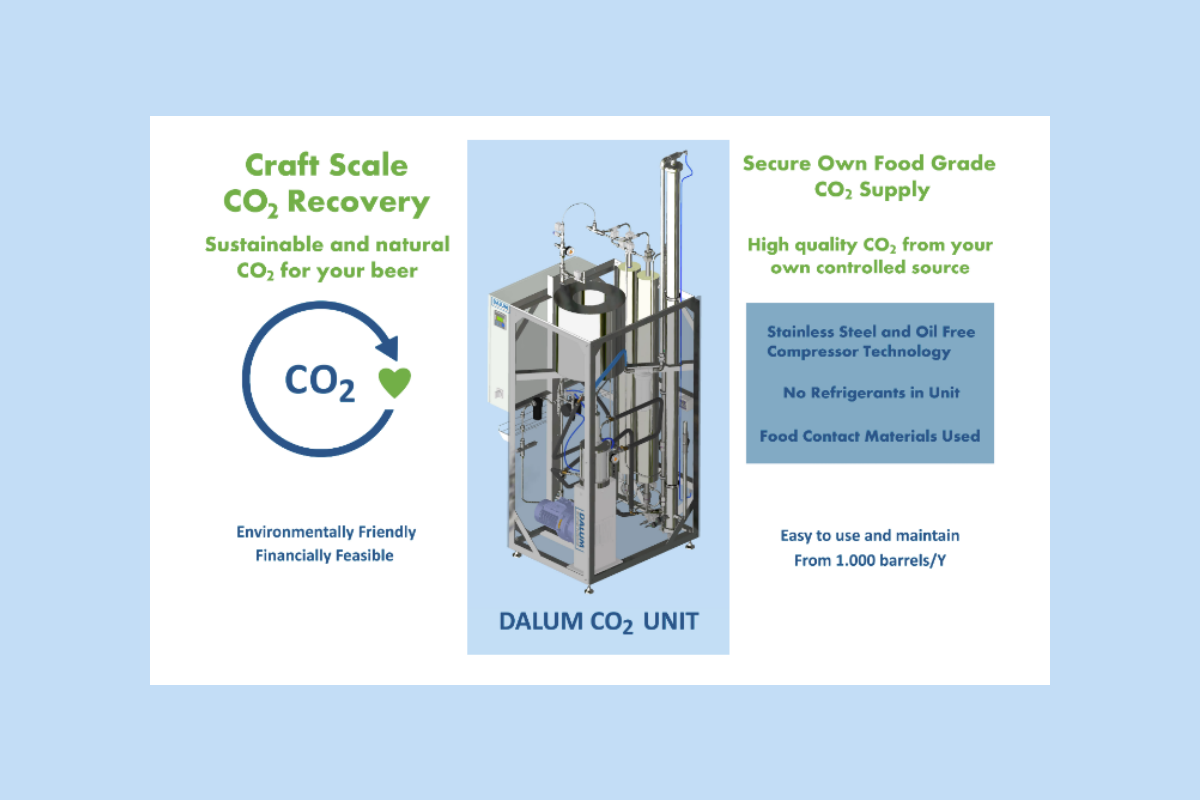

Dalum’s mission is to make a significant contribution to the reduction of global CO2 emissions in the craft brewing market by providing a state-of-the-art product at a financially feasible level. “We look forward to announcing some new partnerships soon and working with more craft brewers who are as passionate about craft brewing as we are. Looking forward seeing everyone at the Craft Brewers Conference in Nashville,” says Kim Dalum, Dalum’s founder.

PRESS RELEASE