Rice is showing potential to play a more prominent role in beer brewing, and it helps that Arkansas produces a lot of it.

Arkansas grows about half of the rice in the United States, mostly long-grain. Meanwhile, climate change and international conflicts are leading to a shortage of the raw materials traditionally used for brewing beer, especially barley.

A new study titled “Investigating the Malting Suitability and Brewing Quality of Different Rice Cultivars,” published in February by the Beverages journal, suggests the potential for malted rice to yield robust fermentations in gluten-free, all-malt beer and also in styles that use high adjunct inclusions. An adjunct is an additional source of sugar for beer fermentation.

Rice and corn have been used as an adjunct grain by American brewers since the 1860s. But the rice has been milled white rice, and not malted. Since the malting qualities of U.S. rice cultivars had not yet been evaluated for brewing qualities, one goal of the study was to identify rice cultivars with high malting potential.

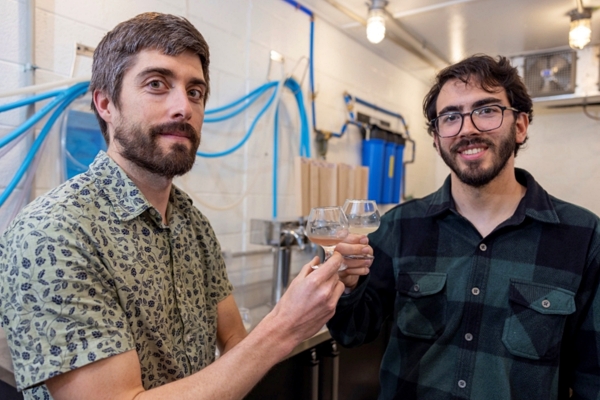

Scott Lafontaine, left, flavor chemist and assistant professor in the U of A Food Science Department, stands with food science graduate student Bernardo P. Guimaraes in the U of A Beverage Development Facility with beers made from malted rice as part of a year-long study with the Arkansas Agricultural Experiment Station.

U of A food science graduate student Bernardo P. Guimaraes was the lead author of the malted rice study, which provides the first publicly available data on 19 rice varieties important to the U.S. rice industry that were malted and analyzed for brewing qualities. Scott Lafontaine, a flavor chemist and assistant professor in the Food Science Department, served as Guimaraes’ adviser on the research.

“Does rice have what it takes? Scientifically, yes, it is possible,” Lafontaine said.

They have found rice malts with enough enzymatic capacity to fully convert their starch source into fermentable sugar, also known as self-saccharifying malts, that produce a sugary liquid called “wort” in brewing. Lafontaine says the wort from rice malt “seems to yield healthy fermentations with a standard yeast, without adding enzymes or nitrogen supplementation.”

Lafontaine and Guimaraes are both part of the Dale Bumpers College of Agricultural, Food and Life Sciences at the U of A and the Arkansas Agricultural Experiment Station. The experiment station is the research arm of the U of A System Division of Agriculture.

NO EXTRA VESSEL WITH RICE MALT?

Malting is the process of germinating a grain through hydration and then drying and heating it to halt germination. The process forms enzymes required to turn the starch into sugar when soaked in hot water for the phase of brewing called “mashing.” Where rice is concerned, brewers have typically used milled white rice and not rice malt. Using milled white rice calls for an additional brewing vessel because it needs to be boiled to gelatinize the starch so it can be converted into that sugary liquid called wort.

Malted rice, on the other hand, may not require a second vessel. Guimaraes and Lafontaine showed the malted rice to be self-saccharifying with the appropriate mashing conditions. In other words, with the right temperature and time, the starch could be broken down to fermentable sugars that yeast can assimilate and turn into alcohol.

As wheat flour is to bread, malted barley is to beer, with recipes calling for varying levels of a barley as a base malt along with other grains like wheat, rye and oats for different styles of beer. Additional ingredients like roasted barley, and roasted malted barley, develop different flavors and aromas.

In the study, long-grain rice when malted showed the most promise as a competitor to malted barley for sugar content and other brewing qualities. The study looked at short, medium and long-grain varieties of “paddy rice,” or rice with the chaff removed but not the husk. Interestingly, wild varieties of rice that had purple-pigmented brans produced naturally colored gluten-free beers with hues similar to wine.

NEW FINDINGS

Previous public studies on rice malt were performed on Italian and Indian varieties, and the study of U.S. rice malts offered two interesting discoveries, Lafontaine said. For one, the rice varieties had different gelatinization temperatures and mashing parameters seemed to have an impact on the onset of gelatinization.

“While we are not sure exactly what is occurring yet, this is likely due to the unique enzymatic profile of the rice malts and shows that brewers just have to alter their mashing conditions to effectively leverage this material in the brewery,” Lafontaine said of the lower gelatinization temperatures.

The other unexpected finding was that the malted rice showed higher protein levels than previously reported, which offers potential applications as an alternative protein source in foods, Lafontaine said. The new study showed the protein content ranged from 7% to 10.5%, and some rice cultivars had protein content comparable to malted barley.

Depending on the variety of rice grown, the study indicates the potential for a value-added product for farmers whose rice turns up with a high level of chalkiness during milling. Chalky rice is opaque and tends to break when being processed, making it less valuable as a food product. However, chalkiness would not have as much of a bearing on quality if sent to a maltster and turned into rice malt. High nighttime temperatures during a rice kernel’s development have been shown to contribute to chalkiness. As the climate warms, this will be a continual issue for farmers and scientists to contend with, Lafontaine noted.

ECONOMICS AND FLAVOR

Although the chemical analysis of the malted rice is promising, Lafontaine is working with the Agricultural Economics and Agribusiness Department to conduct a feasibility study considering many economic factors that compare malted rice and malted barley.

One of the most pressing economic factors is the cost of barley, which has increased in the past four years. The increase has made long-grain rice “cost equivalent” to barley, Lafontaine said. Barley is grown in areas with cooler climates, while rice is grown in warmer climates. So, climate change and global warming are other factors for long-term economic impacts of barley and rice as beer ingredients, he added.

“By offering a more locally sourced grain for Southern and U.S. brewers, despite paddy rice being proportionally more carbon dioxide intensive to grow than malted barley, the lack of international shipping may potentially make up the difference in carbon dioxide,” the study notes. “Additionally, rice is a gluten-free source of starch for brewers and beverage/food producers.”

Lafontaine intends to conduct a sensory panel with the various beers produced from rice malt. He and Guimaraes have noticed, for example, that some aromatic varieties of rice produced elevated levels of diacetyl, which has a buttery popcorn aroma often considered an off flavor in beer.

“As a sneak peak of the next part of this study, I can say that the rice varieties had many different and interesting aromas and flavors,” Guimaraes said. “I firmly believe they have great potential either as a stand-alone raw material or in conjunction with barley malt.”

The rice varieties were malted in small quantities during the study using techniques comparable to industry standards. With each small test batch, the researchers measured protein content, enzyme levels and other characteristics important to brewing. Lafontaine’s lab is licensed and bonded as the U of A Beverage Development Facility with an electric, 15-gallon brewing system to provide hands-on experience to students in the U of A Certificate of Proficiency in Brewing Science program.

Collaborators on the study included rice breeders at the Division of Agriculture’s Rice Research and Extension Center, researchers with the Arkansas Agricultural Experiment Station’s Rice Processing Program, the U.S. Department of Agriculture’s Dale Bumpers National Rice Research Center in Stuttgart and Versuchs-und Lehranstalt für Brauerei in Berlin, Germany.

SOURCE: University of Arkansas (Press Release)

PHOTO CREDIT: U of A System Division of Agriculture / Paden Johnson