Ingersoll Rand Creates Oil-less Air Compressors

For breweries, compressed air is an important element used for several components to operate a variety of applications including canning, bottling and kegging as well as processes like wort aeration. Traditionally, brewers tend to use oil-lubricated compressors, however when compressed air is used in direct contact with mash, wort, beer, vessels or piping, trace amounts of oil can adversely affect the beer quality.

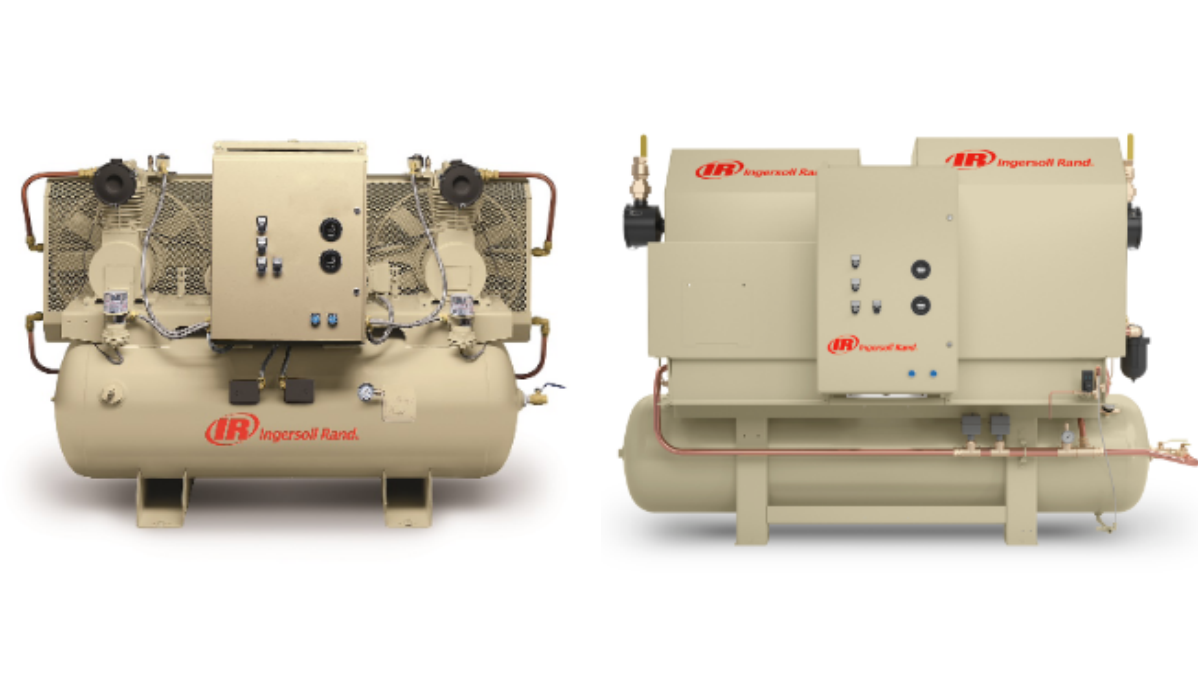

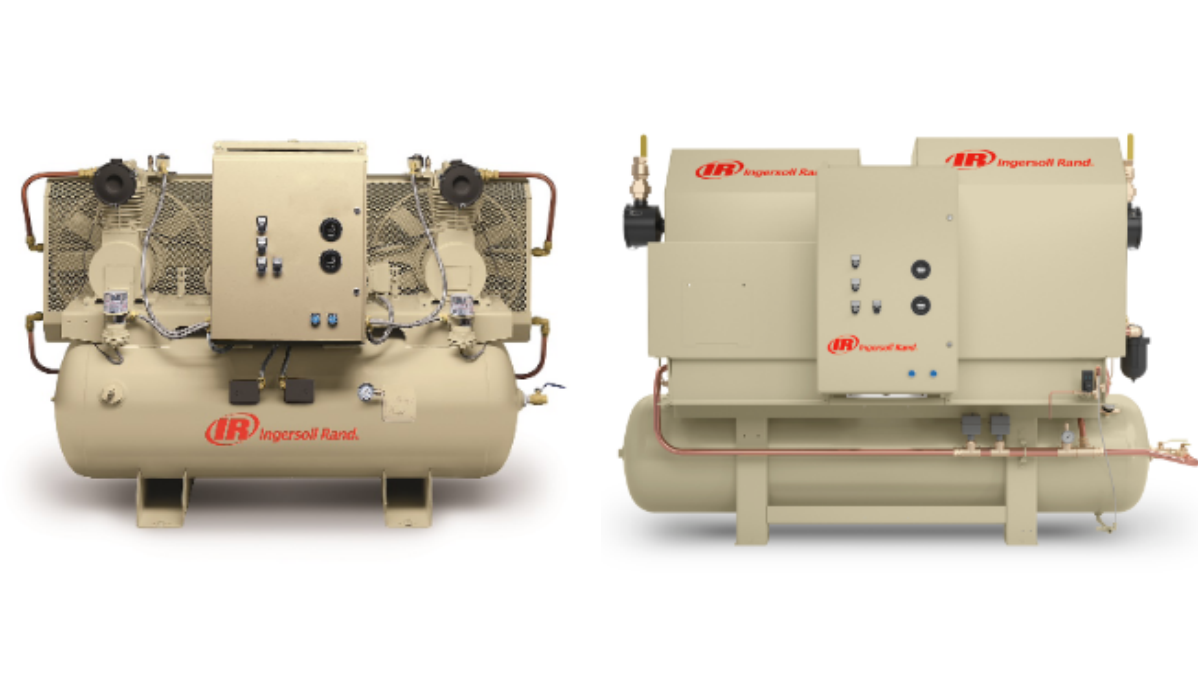

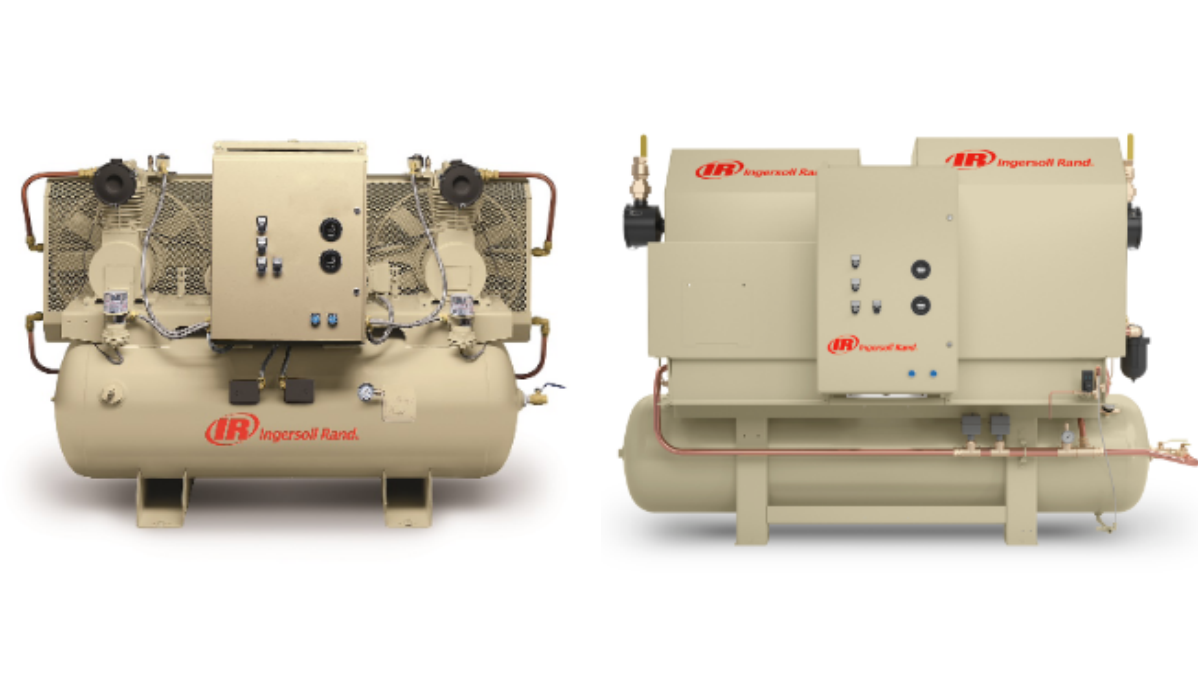

Ingersoll Rand has just introduced a new range (1- to 15-hp) of oil-less air producers – IR’s Oil-Less Reciprocating Air Compressor. These oil-less units can utilize this clean air power via:

For more information, click here.